- Home

- Products

- Self Drilling Screw

- Self Drilling Screw TEK With Wings

The special design of the end of the drill point allows the self-drilling screw to integrate three functions: "Drilling", "Tapping" and "Locking" on one screw. It's surface hardness and core hardness are higher than ordinary self-tapping screws. The biggest advantage of the self-drilling screw is it can save construction time and cost-effectiveness. Therefore, the field of application becomes wider than we expected before.

And the drilling screw with wings improved the chip removal function and heat generation when drilling. Not only promote the unique of the product but also improve its competitiveness. And the market demonstrates, Top Green’s product can tap wood sections faster than general products and penetrate steel smoothly to fit tight. This advantage could satisfy the market demand of advanced countries and create high-value products and income to transform the traditional fastener industry into a high-value class industry.

In manufacturing, we could form the drilling point and the wind at once. With this screw, the connection of thick wood and steel can be completed at once. Using the developed screws in this project, the screw locking time can be reduced from 25 seconds to 7 seconds, which greatly saved operation time and reduced the energy used, achieving the effect of energy saving and carbon reduction.

And the drilling screw with wings improved the chip removal function and heat generation when drilling. Not only promote the unique of the product but also improve its competitiveness. And the market demonstrates, Top Green’s product can tap wood sections faster than general products and penetrate steel smoothly to fit tight. This advantage could satisfy the market demand of advanced countries and create high-value products and income to transform the traditional fastener industry into a high-value class industry.

In manufacturing, we could form the drilling point and the wind at once. With this screw, the connection of thick wood and steel can be completed at once. Using the developed screws in this project, the screw locking time can be reduced from 25 seconds to 7 seconds, which greatly saved operation time and reduced the energy used, achieving the effect of energy saving and carbon reduction.

The characters of Wing TEK Screws

- The tail and wings are formed at once. - It can effectively simplify the manufacturing process and save man-hours and reduce production costs.

- Instead of the old pinch processing. - The product quality could be ensured, and the design function of the wings is also improved, with this screw, the connection of thick wood and steel can be completed at once. Satisfied customer requirements, create high-quality (value) products, and helped them develop international markets. Wide application: Floor decoration, Truck body, Inner bottom of the container (thick solid wood board and asbestos and steel plate joint).

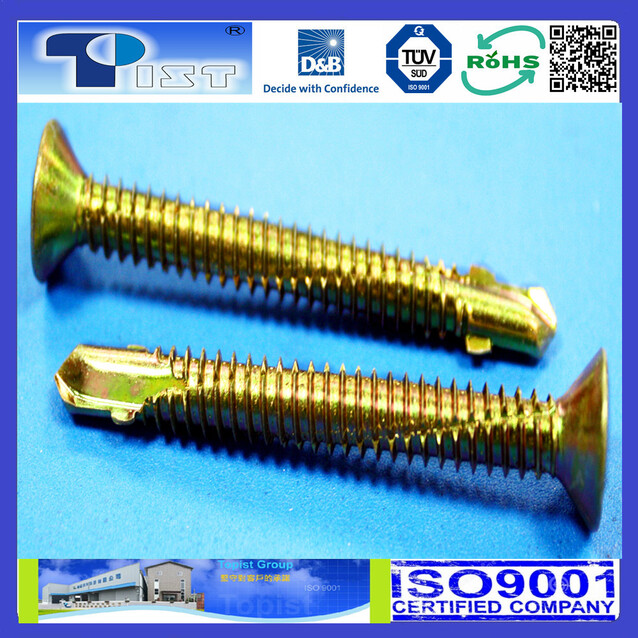

Flat Head, Phil, Self Drilling Screw With Wings, With Three Cutting lines on Thread, Yellow Zinc Pla

Flat Head, Phil, Self Drilling Screw With Wings, Yellow Zinc Plated

Flat Head, Phil, With Serration Under Head, Self Drilling Screw With Wings, Zine Plated

Double Flat Head, Phil, With Serration Under Head, Self Drilling Screw With Wings, Shank Slotted, Zi

Flat Head, Phil, With Serration Under Head, Self Drilling Screw With Wings, Gold Dacromet

Flat Head, Phil, Self Drilling Screw With Wings, Green Dacromet

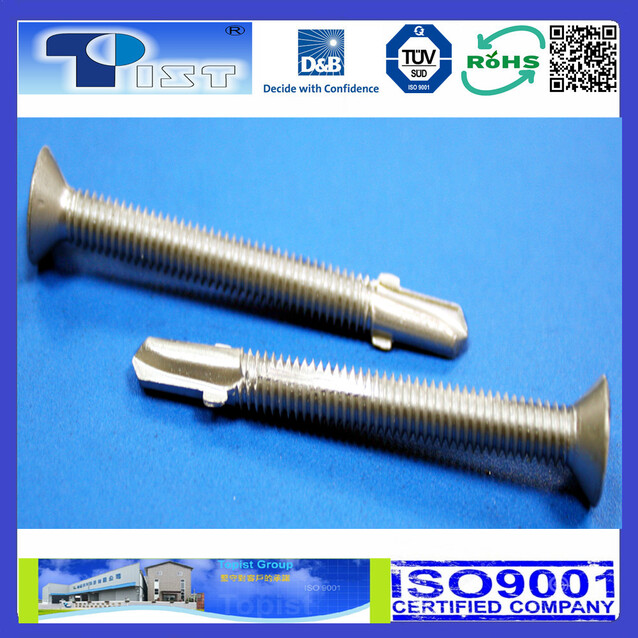

Flat Head, Phil, Self Drilling Screw With Wings, Silver White Ruspert

Flat Head, Phil, With Serration Under Head, Self Drilling Screw With Wings, Zine Plated

Flat Head, Phil, Self Drilling Screw With Wings, With Three Cutting lines on Thread, Silver White Ru